In general, leather is sold in four forms

Full-grain leather refers to hides that have not been sanded, buffed, or snuffed (as opposed to top-grain or corrected leather) to remove imperfections (or natural marks) on the surface of the hide. The grain remains allowing the fiber strength and durability. The grain also has breathability, resulting in less moisture from prolonged contact. Rather than wearing out, it will develop a patina over time. High quality leather furniture and footwear are often made from full-grain leather. Full-grain leathers are typically available in two finish types: aniline and semi-aniline.

Top-grain leather or semi corrected leather (the most common type used in high-end leather products) is the second-highest quality. It has had the “split” layer separated away, making it thinner and more pliable than full-grain. Its surface has been sanded and a finish coat added to the surface which results in a colder, plastic feel with less breathability, and it will not develop a natural patina. It is typically less expensive and has greater resistance to stains than full-grain leather, so long as the finish remains unbroken.

Corrected-grain leather is any leather that has had an artificial grain applied to its surface. The hides used to create corrected leather do not meet the standards for use in creating vegetable-tanned or aniline leather. The imperfections are corrected or sanded off, and an artificial grain impressed into the surface and dressed with stain or dyes. Most corrected-grain leather is used to make pigmented leather as the solid pigment helps hide the corrections or imperfections. Corrected grain leathers can mainly be bought as two finish types: semi-aniline and pigmented.

Split leather (SPLITS) is leather created from the fibrous part of the hide left once the top-grain of the rawhide has been separated from the hide. During the splitting operation, the top-grain and drop split are separated. The drop split can be further split (thickness allowing) into a middle split and a flesh split. In very thick hides, the middle split can be separated into multiple layers until the thickness prevents further splitting. Split leather then has an artificial layer applied to the surface of the split and is embossed with a leather grain (bycast leather). Splits are also used to create suede. The strongest suedes are usually made from grain splits (that have the grain completely removed) or from the flesh split that has been shaved to the correct thickness. Suede is “fuzzy” on both sides. Manufacturers use a variety of techniques to make suede from full-grain. A reversed suede is a grained leather that has been designed into the leather article with the grain facing away from the visible surface. It is not considered to be a true form of suede.

The following are not “true” organic leathers, but are materials that contain leather fiber. Depending on jurisdiction, they may still be labeled as “Genuine Leather”, even though the consumer generally can only see the outer layer of the material and can’t actually see any of the leather content:

Bycast leather is a split leather with a layer of polyurethane laminated to the surface and then embossed. Bycast was originally made for the shoe industry and later adopted by the furniture industry. The original formula created by Bayer was strong but expensive. The result is a material that is slightly stiffer but cheaper than top-grain leather but has a much more consistent texture. Because its surface is completely covered in plastic, is easier to clean and maintain, but is not easily repaired.

Bonded leather or “Reconstituted leather” is an economical type that uses leftovers of organic leather (often from leather tanneries or leather workshops) which are shredded and then bonded together with polyurethane binders or latex on top of a fiber sheet. The varying degree of organic leather in the mix (between 10% and 90%) affects the smell and the texture of such product. Due to its reduced cost it is becoming a popular choice for furniture upholstery, especially for commercial use, where durability is needed; however durability can vary widely, depending on the formulation.

Artificial leather or American leather cloth, a large quantities of a material having a more or less leather-like surface were once used, principally for upholstery purposes, such as the covering of chairs, lining the tops of writing desks and tables, and so on.

There was considerable diversity in the preparation of such materials. A common variety consisted of a web of calico coated with boiled linseed oil mixed with dryers and lampblack or other pigment. Several coats of this mixture were uniformly spread, smoothed and compressed on the cotton surface by passing it between metal rollers, and when the surface was required to possess a glossy enamel-like appearance, it received a finishing coat of copal varnish. A grained Morocco surface was given to the material by passing it between suitably embossed rollers.

Preparations of this kind have a close affinity to cloth waterproofed with rubber, and to such manufactures as ordinary wax cloth. An artificial leather which was patented and proposed for use as soles for boots, etc., was composed of powdered scraps and cuttings of leather mixed with solution of guttapercha dried and compressed. In place of the guttapercha solution, oxidized linseed oil or dissolved resin could be used as the binding medium for the leather powder.

Less-common leathers include:

Buckskin or brained leather is a tanning process that uses animal brains or other fatty materials to alter the leather. The resulting supple, suede-like hide is usually smoked heavily to prevent it from returning to a rawhide state, if wetted. It will be easier to soften, and will help keep leather eating bugs away.

Patent leather is leather that has been given a high-gloss finish. The original process was developed in Newark, New Jersey, by inventor Seth Boyden in 1818. Patent leather usually has a plastic coating.

Fish Leather : leather popular for its motifs and its pigmentation. Mainly used for making shoes and bags, the fish skin is tanned like other animal skins.[2] The species used include salmon, perch, sturgeon, etc.

Salmon : farmed in Iceland and Norway, salmon skin has fine scales. Its strength and elegant look make it the most popular fish leather.

Perch : coming from Nile, its skin is recognizable with its large, round and soft scales.

Wolffish : its skin is smooth because without scales. We recognize it thanks to its dark spots, and the ‘stripes’ which are due to the friction of marine rocks.

Cod : its skin has finer scales than salmon, but its texture is more varied, sometimes smooth and sometimes rough.

Sturgeon : fish well known for its eggs (caviar), which make it rare. Its leather is thus quite expensive.

Eel : fish without scales, its skin has a shiny appearance.

Tilapia : its leather is less resistant than salmon and perch but is still exotic. It comes mainly from Africa (Nile).

Shagreen is also known as stingray skin/leather. Applications used in furniture production date as far back as the art deco period. The word “shagreen” originates from France. It’s known as the most difficult leather to work due to dished scales of the animal, and it is one of the most expensive leathers.

Shark : its skin is covered with small, close-set tubercles, making it very tough. The handbags made of shark skin used to be in vogue but this keen interest has since fallen as the costs of production and of the leather itself are very high. Moreover, this skin is more difficult to work. Should not be confused with traditional “sharkskin”, a woven textile product.

Vachetta leather is used in the trimmings of luggage and handbags. The leather is left untreated and is therefore susceptible to water and stains. Sunlight will cause the natural leather to darken in shade, called a patina.

Slink is leather made from the skin of unborn calves. It is particularly soft and is valued for use in making gloves.

Deerskin is a tough leather, possibly due to the animal’s adaptations to its thorny and thicket-filled habitats.[citation needed] Deerskin has been used by many societies, including indigenous Americans. Most modern deerskin is no longer procured from the wild, with deer farms breeding the animals specifically for the purpose of their skins. Large quantities are still tanned from wild deer hides in historic tanning towns such as Gloversville and Johnstown in upstate New York. Deerskin is used in jackets and overcoats, martial arts equipment such as kendo and bogu, as well as personal accessories such as handbags and wallets.

Nubuck is top-grain cattle hide leather that has been sanded or buffed on the grain side, or outside, to give a slight nap of short protein fibers, producing a velvet-like surface.

Russia leather is a particular form of bark-tanned cow leather. It is distinguished by an oiling step, after tanning, where birch oil is worked into the leather to make it particularly hard-wearing, flexible and resistant to water.

There are two other types of leather commonly used in specialty products, such as briefcases, wallets, and luggage:

Belting leather is a full-grain leather that was originally used in driving pulley belts and other machinery. It is found on the surface of briefcases, portfolios, and wallets, and can be identified by its thick, firm feel and smooth finish. Belting leather is generally a heavy-weight of full-grain, vegetable-tanned leather.

Napa leather is chrome-tanned and is soft and supple. It is commonly found in wallets, toiletry kits, and other personal leather goods.

Hannitan

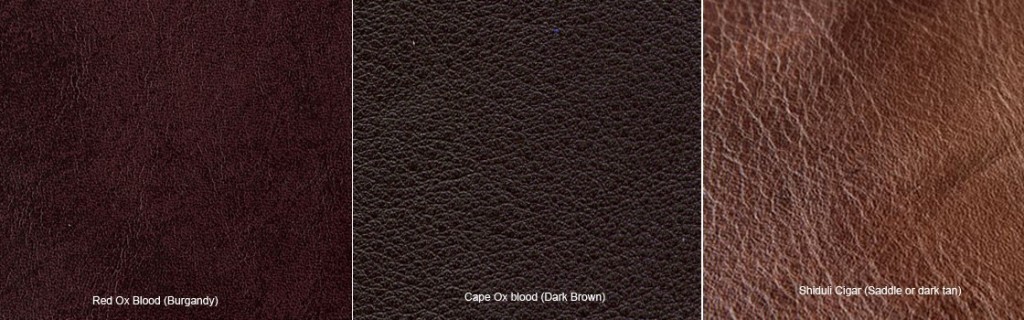

Hannitan Leather, under the management of Rudolf Hanni, has been hailed by many as one of the cleanest and efficient tanneries in the world. Starting from very humble beginnings Hannitan has expanded into the largest supplier of furniture leather in South Africa, producing an average of 1,200 hides daily. The tannery produces a wide variety of upholstery leathers including, aniline leathers, semi-aniline, full grain, corrected grain, buffed leathers and oil pull-ups in a huge selection of colours.

Hannitan produces a wide variety of leathers in any given colour – subject to quantities, mainly soft upholstery leathers, nappa shoe leathers and leather goods.